Flatness ndizovuta kwambiri kulolerana kwa geometric mu Machining, makamaka pama sheet zitsulo ndi ma CNC machining process. Zimatanthawuza momwe mfundo zonse pamtunda zimakhala zofanana ndi ndege yowonetsera.

Kupeza flatness ndikofunikira pazifukwa izi:

1. Kagwiridwe ntchito:Zigawo zambiri ziyenera kugwirizana bwino. Ngati mbalizo sizili zophwanyika, zingayambitse kusagwirizana ndi kusokoneza ntchito yonse ya msonkhano.

2. Kugawa Katundu:Flat surface imatsimikizira kugawa katundu. Malo osagwirizana angayambitse kupsinjika maganizo komwe kungapangitse kuti chigawocho chiwonongeke msanga.

3. Ubwino Wokongola:M'mafakitale omwe mawonekedwe ndi ofunikira, monga zamagetsi zamagalimoto ndi ogula, kusalala kumathandiza kukonza mawonekedwe a chinthucho.

4. Kuchita Bwino kwa Msonkhano:Zigawo zosagwirizana zimatha kusokoneza dongosolo la msonkhano, zomwe zimapangitsa kuti pakhale ndalama zogwirira ntchito komanso nthawi.

5. Kulondola kwa makina owonjezera:Kuphwanyidwa nthawi zambiri kumakhala kofunikira kuti mugwiritse ntchito makina otsatizana monga kubowola kapena mphero, kumene malo ophwanyika amafunika kuti mupeze zotsatira zolondola.

Pitirizani kukhala flatness panthawi processing

Kukwaniritsa ndi kusunga flatness pa makina kumafuna kukonzekera mosamala ndi kuphedwa. Nazi njira zina:

1. Kusankha Zinthu:Sankhani zinthu zomwe sizili zophweka kupotoza kapena kupunduka panthawi yokonza. Zitsulo zokhala ndi ma coefficients otsika pakukulitsa kutentha nthawi zambiri zimakondedwa.

2. Zokonza Zolondola:Gwiritsani ntchito zida zoyenera kuti mugwiritsire ntchito chogwirira ntchito panthawi yokonza. Izi zimachepetsa kusuntha ndi kugwedezeka komwe kungayambitse nkhondo.

3. Magawo owongolera makina:Konzani liwiro la kudula, chakudya ndi kuya kwa kudula. Kutentha kwakukulu komwe kumapangidwa panthawi yokonza kungayambitse kuwonjezereka kwa kutentha ndi kumenyana.

4. Sequential Machining:Ngati ndi kotheka, magawo amakina mu magawo. Izi zimathandiza kuti zinthu zichotsedwe mwadongosolo, kuchepetsa chiopsezo cha deformation.

5. Pambuyo pokonza chithandizo:Ganizirani njira zochepetsera kupsinjika monga post-processing annealing kapena normalizing kuti muchepetse kupsinjika kwamkati komwe kungayambitse nkhondo.

6. Kugwiritsa Ntchito Flat Reference Surface:Yang'anani nthawi zonse ndikuwongolera zida zamakina kuti muwonetsetse kuti zikuyenda pamtunda wokhazikika.

Onani flatness

Kuonetsetsa kutizida zamakinakukumana ndi mawonekedwe a flatness, njira zoyenera zowunikira ziyenera kugwiritsidwa ntchito:

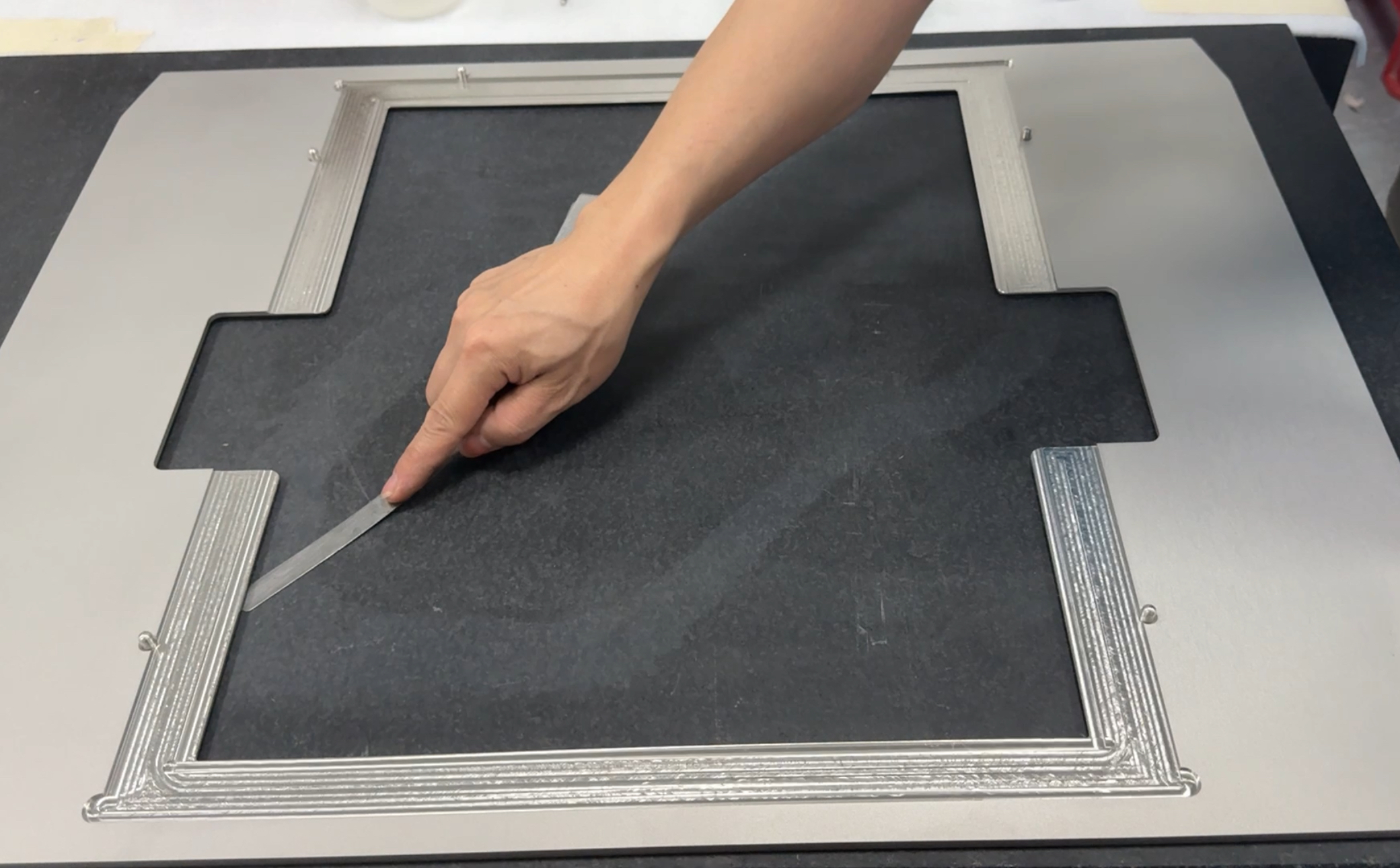

1. Kuyang'anira Zowoneka:Kuyang'ana kosavuta nthawi zina kumatha kuwulula zovuta zowoneka bwino, monga mipata pansi pa gawo kapena kuwala komwe kumadutsa.

2. Njira Yolamulira:Ikani chowongolera cholondola pamwamba ndikugwiritsa ntchito choyezera kuti muyese mipata iliyonse. Njirayi ndiyothandiza kwambiri pakuwunika mwachangu.

3. Chizindikiro Choyimba:Chizindikiro choyimba chingagwiritsidwe ntchito kuyeza kupatuka kwa flatness kwa malo onse. Njirayi imapereka miyeso yolondola kwambiri.

4. Coordinate Measuring Machine (CMM):Pazolemba zolondola kwambiri, CMM ingagwiritsidwe ntchito kuyeza kusalala kwa pamwamba potenga mfundo zingapo ndikuwerengera kupatuka kwa ndege yolozera.

5. Njira Yowonera Ndege:Izi zimaphatikizapo kugwiritsa ntchito ndege ya kuwala ndi kuwala kwa monochromatic kuti muwone kusalala. Zizindikiro zosokoneza zimatha kuwonetsa kupatuka.

6. Kusanthula kwa Laser:Ukadaulo wapamwamba wa sikani wa laser umapereka mamapu atsatanetsatane apamtunda, kulola kusanthula kwathunthu kwa kusalala.

Pomaliza

Flatness ndi gawo lofunikira pakukonza, kukhudza magwiridwe antchito, kukongola komanso kusanja bwino kwa msonkhano. Pomvetsetsa kufunikira kwake ndikugwiritsa ntchito njira zosamalira ndi kuyang'anira kusanja,HY METALS imatha kutsimikizira kupanga zida zapamwamba kwambiri zomwe zimakwaniritsa kulolerana kolimba. Kuyang'ana pafupipafupi komanso kutsatira njira zabwino zogwirira ntchito kumathandizira kuti zinthu ziziwayendera bwino komanso kuti kasitomala asangalale.

HY Zitsulokuperekakuima kumodzi ntchito zopangira mwamakonda kuphatikizapo kupanga mapepala achitsulondiCNC makina,Zaka 14 zakuchitikirandi8 malo okhala ndi zonse.

Zabwino kwambiriUbwinokuwongolera, mwachiduletembenuka,chachikulukulankhulana.

Tumizani wanuRFQ ndizojambula mwatsatanetsatane lero. Tikulemberani mawu ASAP.

WeChat:ndi09260838

Uzani:+ 86 15815874097

Imelo:susanx@hymetalproducts.com

Nthawi yotumiza: Oct-10-2024